Titanium Stub Ends

Usually, titanium stub ends are used with ASME B16.5 carbon steel backing flanges (lap joint flanges) in pipeline to minimize the cost while maintaining excellent corrosion resistance to fluid. The stub ends may be furnished in short pattern or long pattern in accordance with ASME B16.9. The material covers Grade 1, Grade 2, Grade 3, Grade 5, Grade 7, Grade 9, Grade 12, Grade 16 titanium and its alloys, which shall be made in accordance with ASTM B363. For sizes NPS 6 and smaller, the titanium stub ends will be furnished in seamless type (ASTM B861); for sizes larger than NPS 6, the titanium stub ends will be furnished in welded type (ASTM B265). Application of titanium stub ends: pulp and paper industry, water and seawater service, chemical processes involving oxidizing media and oxidizing acids.

Grade 2 titanium stub ends: short pattern and long pattern.

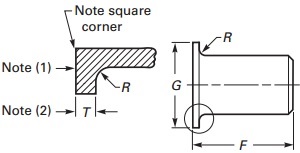

Drawings & Dimensions for Titanium Stub Ends

Drawing of titanium stub ends acc. to ASME B16.9

| Nominal Size | Outside Diameter of Barrel | Long Pattern Length, F | Short Pattern Length, F | Radius of Fillet, R | Diameter of Lap, G |

|

|---|---|---|---|---|---|---|

| NPS | Max. mm. in. | Min. mm. in. | mm. in. | mm. in. | mm. in. | mm. in. |

| 1/2 | 22.8 0.896 | 20.5 0.809 | 76 3.00 | 51 2.00 | 3 0.12 | 35 1.38 |

| 3/4 | 28.1 1.106 | 25.9 1.019 | 76 3.00 | 51 2.00 | 3 0.12 | 43 1.69 |

| 1 | 35.0 1.376 | 32.6 1.284 | 102 4.00 | 51 2.00 | 3 0.12 | 51 2.00 |

| 1 1/4 | 43.6 1.716 | 41.4 1.629 | 102 4.00 | 51 2.00 | 5 0.19 | 64 2.50 |

| 1 1/2 | 49.9 1.965 | 47.5 1.869 | 102 4.00 | 51 2.00 | 6 0.25 | 73 2.88 |

| 2 | 62.4 2.456 | 59.5 2.344 | 152 6.00 | 64 2.50 | 8 0.31 | 92 3.62 |

| 2 1/2 | 75.3 2.966 | 72.2 2.844 | 152 6.00 | 64 2.50 | 8 0.31 | 105 4.12 |

| 3 | 91.3 3.596 | 88.1 3.469 | 152 6.00 | 64 2.50 | 10 0.38 | 127 5.00 |

| 3 1/2 | 104.0 4.096 | 100.8 3.969 | 152 6.00 | 76 3.00 | 10 0.38 | 140 5.50 |

| 4 | 116.7 4.593 | 113.5 4.469 | 152 6.00 | 76 3.00 | 11 0.44 | 157 6.19 |

| 5 | 144.3 5.683 | 140.5 5.532 | 203 8.00 | 76 3.00 | 11 0.44 | 186 7.31 |

| 6 | 171.3 6.743 | 167.5 6.594 | 203 8.00 | 89 3.50 | 13 0.50 | 216 8.50 |

| 8 | 222.1 8.743 | 218.3 8.594 | 203 8.00 | 102 4.00 | 13 0.50 | 270 10.62 |

| 10 | 277.2 10.913 | 272.3 10.719 | 254 10.00 | 127 5.00 | 13 0.50 | 324 12.75 |

| 12 | 328.0 12.913 | 323.1 12.719 | 254 10.00 | 152 6.00 | 13 0.50 | 381 15.00 |

| 14 | 359.9 14.170 | 354.8 13.969 | 305 12.00 | 152 6.00 | 13 0.50 | 413 16.25 |

| 16 | 411.0 16.180 | 405.6 15.969 | 305 12.00 | 152 6.00 | 13 0.50 | 470 18.50 |

| 18 | 462.0 18.190 | 456.0 17.969 | 305 12.00 | 152 6.00 | 13 0.50 | 533 21.00 |

| 20 | 514.0 20.240 | 507.0 19.969 | 305 12.00 | 152 6.00 | 13 0.50 | 584 23.00 |

| 22 | 565.0 22.240 | 558.0 21.969 | 305 12.00 | 152 6.00 | 13 0.50 | 641 25.25 |

| 24 | 616.0 24.240 | 609.0 23.969 | 305 12.00 | 152 6.00 | 13 0.50 | 692 27.25 |

*Gasket face finish shall be in accordance with ASME B16.5 for raised face flanges.

*The lap thickness, T, shall not be less than nominal pipe wall thickness.

*Short pattern titanium stub ends are applicable for ASME B16.5 flanges of 300#, 600#, and 900#.

*Long pattern titanium stub ends are applicable for AMSE B16.5 flanges of 1500# and 2500#.

*Custom-designed titanium stub ends can be manufactured upon request.