SS316 / SS316L

Stainless steel 316 (SS316) is an austenitic chromium-nickel stainless steel containing deliberate amount of molybdenum which increases general corrosion resistance and especially improves its pitting resistance to chloride ion solutions. The molybdenum addition also provides increased strength at elevated temperatures. Thus, SS316 is also known as “Mo-Added” version of SS304. Stainless steel 316L (SS316L) is the extra-low carbon version of SS316 that minimizes harmful carbide precipitation during welding. Both SS316 and SS316L have exceptional resistance to corrosion against sulfuric, hydrochloric, acetic, formic, and tartaric acids; as well as against acid sulfates and alkaline chlorides. They are widely used in exhaust manifolds, heat exchangers, pharmaceutical equipment, cryogenic piping, valve and pump trims, chemical & petrochemical process, pulp and paper industry, and food industry, etc.

ASTM A182 F316L S/O & W/N flanges, 150#.

1. UNS Designation & International Equivalent

| Type | UNS | JIS | EN/DIN | EN/BS | EN/NF | ISO | GB | GOST |

|---|---|---|---|---|---|---|---|---|

| 316 | S31600 | SUS316 | X5CrNiMo17-12-2 | 316S31 | Z7CND17-12-2 | 20 | 0Cr17Ni12Mo2 | 08KH17H13M2T |

| 316L | S31603 | SUS316L | X2CrNiMo18-14-3 | 316S13 | X2CrNiMo17-12-2 | 19 | 00Cr17Ni14Mo2 | 03KH17H14M2 |

2. Product Forms and Standards of SS316/ SS316L

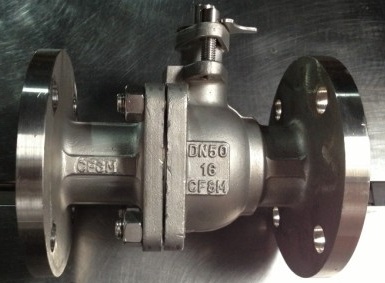

A floating ball valve, 2″ PN16 split body, with ASTM A351 CF8M (SS316) body.

| Product Forms | Material Standards |

|---|---|

| Plates, Sheets & Strips | ASTM A240, A666 |

| Billets, Bars & Rods | ASTM A276, A314, A479 |

| Forgings(Flanges & Fittings) | ASTM A182, A473. |

| Wires | ASTM A313, A368, A478, A492, A493, A580. |

| Seamless and Welded Pipes | ASTM A312, A358, A813, A814. |

| Wrought Pipe Fittings | ASTM A403 |

| Castings(Cast Fittings & Valve Parts) | ASTM A351, A743, A744 |

3. Physical Properties of SS316/ SS316L

| Density | Melting Range | Specific Heat | Magnetic Permeability | Electric Resistivity |

|---|---|---|---|---|

| g/cm3 | °F | kJ/kg*K | Oersteds | microhm-cm |

| 7.99 | 2500-2550 | 0.50 | ≤1.02 | 74 |

4. Chemical Composition of SS316/ SS316L

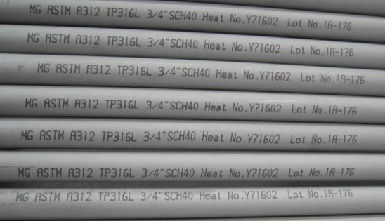

ASTM A312 TP316L seamless pipes, 3/4″ SCH40.

| Element | SS316 | SS316L |

|---|---|---|

| Carbon | ≤0.08 | ≤0.03 |

| Manganese | ≤2.00 | ≤2.00 |

| Phosphorus | ≤0.045 | ≤0.045 |

| Sulfur | ≤0.030 | ≤0.030 |

| Silicon | ≤0.75 | ≤0.75 |

| Chromium | 16.00-18.00 | 16.00-18.00 |

| Nickel | 10.00-14.00 | 10.00-14.00 |

| Molybdenum | 2.00-3.00 | 2.00-3.00 |

| Nitrogen | ≤0.10 | ≤0.10 |

| Iron | Balance | Balance |

5. Mechanical Properties of SS316/ SS316L

ASTM A403 Gr. WP316L butt welding fittings with sandblasting or mirror finish surface.

| Grades | Tensile Strength ksi(Mpa), min. | Yield Strength, ksi(Mpa) | Elongation, % | Hardness, Rockwell |

|---|---|---|---|---|

| SS316 | 84(579) | 42(290) | 50 | B79 |

| SS316L | 81(558) | 42(290) | 50 | B79 |