Pitting Test on Incoloy 825 Materials

1. ASTM G48 Method A: Ferric Chloride Pitting Test

In order to study the pitting resistance of Incoloy 825 in high chloride-ion environments, pitting test shall be conducted in accordance with ASTM G48 Method A. The specimen is a piece of Incoloy 825 plate of 30 mm x 10 mm x 3 mm manufactured to ASTM B424 UNS N08825. It is immersed into 6% FeCl3 solution at 50(±1)°C. Maintain the test solution temperature for 72 hours. Then, remove the specimen , rinse with water and scrub with a nylon bristle brush under running water to remove corrosion products, dip in acetone or methanol, and air-dry. Weigh the specimen to the accuracy of 0.0001g. Analyze corrosion products at the corrosion pit by using SEM and X-ray EDS methods respectively.

The surface macrostructure of Incoloy 825 after pitting test. Several pitting zones can be clearly observed.

2. Actual Chemical Composition of Incoloy 825 Specimen

| C | S | Si | Mn | P | Ni | Cr | Mo | Nb | Ti | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.0062 | 0.0009 | 0.31 | 0.47 | 0.014 | 43.34 | 22.78 | 3.28 | 0.18 | 0.94 | 2.04 |

3. The SEM & EDS Results

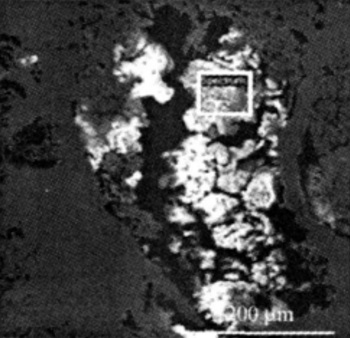

The SEM scanned photo of Incoloy 825 corrosion products.

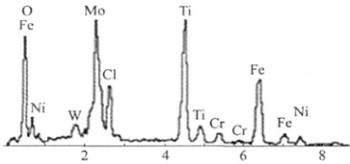

X-ray EDS analysis to determine chemical composition of the corrosion products of Incoloy 825.

The main elements remaining at the corrosion pit are Fe, Mo, Ti and O while the content of base element nickel is relatively low. It is concluded that oxidizing ions react with Cr & Ni in the corrosive solution. The product of the reaction is dissolved in the solution.