Manufacturing Process of Inconel 600 Plates (ASTM B168 Gr. N06600)

Recently, we have supplied approximate 26 metric tonnes of Inconel 600 plates to a HFC-134a project in Brazil. The plates are manufactured to ASTM B168 Grade N06600 specification mainly used for the construction of pressure vessels and reactors. First, the Φ240 electrode bars were made in non-vacuum induction melting furnace(Non-VIM) which were remelted to Inconel 600 Φ360 bars through electroslag remelting process. The products were bloomed to billets sized of 105 mm x 240 mm and 105 mm x 290 mm by using cogging hammer. And they were preliminary rolled to billets sized (19.5~50.5)mm x (260~290)mm and (62~87)mm x (260~290)mm, which were subsequently fed to the Three-High Lauth Plate Mill for precision rolling.

Inconel 600 plate production flow chart 01: melting and remelting.

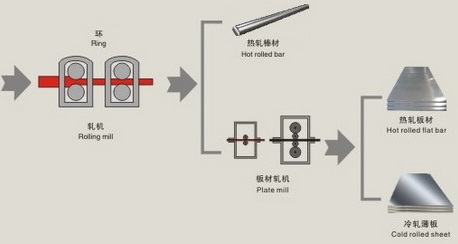

The production flow chart of Inconel 600 plates 02: rough rolling and precision rolling.

Specifically, the following procedures for precision rolling of Inconel 600 plates include: billets examination → hot rolling → annealing → pickling → grinding & cleaning → cold rolling → annealing → pickling → leveling → flattening → cutting → ultrasonic test → final inspection → marking → packaging → storing. The completed products are Inconel 600 sheets of 2 m x 1 m x 2.5 mm and Inconel 600 plates of 2 m x 1.2 m x 6.5 mm; standard: ASTM B168 Gr. N06600. The hot rough rolling & blooming temperature: 1120°C ± 10°C; hot precision rolling temperature: 1090°C ± 10°C; hot rolling maximum deformation rate of each pass: 30%; cold rolling total deformation rate: 30% ~ 40%; annealing temperature for hot-rolled plates: 1000~1020°C; annealing temperature for cold-rolled plates: 980~1000°C; both are air cooling.