Hastelloy C-22

Designated as UNS N06022 or DIN 2.4602, Hastelloy C-22 (also known as “Alloy C-22”), is a nickel-chromium-molybdenum alloy with outstanding resistance to pitting, crevice corrosion, and stress-corrosion cracking. It also exhibits high resistance to oxidizing media, including wet chlorine and mixtures containing nitric and oxidizing acids. Compared to Hastelloy C-276, Hastelloy C-22 has better corrosion resistance in both general conditions or high concentrates of chloride at elevated temperatures as well as other highly oxidizing environments.

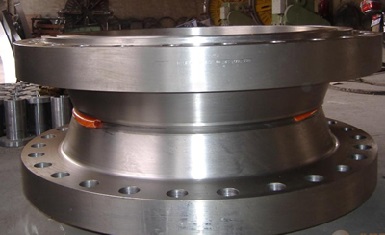

Hastelloy C-22 weld neck flanges, manufactured to ASME B16.47 Series A.

1. Chemical Composition Requirements

| Nominal Chemical Composition of Hastelloy C-22, % | |

|---|---|

| Nickel | Balance |

| Chromium | 22 |

| Molybdenum | 13 |

| Iron | 3 |

| Cobalt | ≤2.5 |

| Tungsten | 3 |

| Manganese | ≤0.5 |

| Silicon | ≤0.08 |

| Carbon | ≤0.01 |

| Vanadium | ≤0.35 |

| Copper | ≤0.5 |

2. Typical Physical Properties

| Density | Electrical Resistivity | Specific Heat | Melting Range | ||||

|---|---|---|---|---|---|---|---|

| lb/in3 | g/cm3 | µohm.in | µohm.m | Btu/lb.°F | J/kg*°C | °F | °C |

| 0.314 | 8.69 | 44.9 | 1.14 | 0.098 | 414 | 2475-2550 | 1357-1399 |

3. Product Forms and Standards of Hastelloy C-22

| Products Form | Standard |

|---|---|

| Sheet, Plate & Strip | ASTM B575 |

| Billet, Rod & Bar | ASTM B574, B472 |

| Coated Electrodes | DIN 2.4638 |

| Bare Welding Rods& Wire | DIN 2.4635 |

| Seamless Pipe & Tube | ASTM B622 |

| Welded Pipe & Tube | ASTM B619, B626 |

| Fittings | ASTM B366, B462 |

| Forgings | ASTM B564, B462 |