Effects of Annealing Temperature on Titanium Grade 2 Seamless Tubes

Recently, we have been supplying titanium grade 2 seamless tubes to a US client in Oregon. The tubes are manufactured in accordance with ASME SB-338 by cross-rolled piercing process.

ASTM B338 titanium grade 2 seamless tubes, Φ25.4 mm x 2.0 mm x 2.6 m.

Two groups of specimens are prepared each of which has two test pieces. The grade 2 titanium test pieces of Group I were annealed at 550°C soaking for 60 minutes, while Group II is annealed at 600°C soaking for 60 minutes. Tensile tests and PMI(spectrum) were performed on each test piece and the mechanical properties and microstructure are obtained respectively.

Effects of Annealing Temp. on Mechanical Properties of Titanium Grade 2

| Group | Specimen | Yield Strength, MPa | Tensile Strength, MPa | Elongation, % |

|---|---|---|---|---|

| I | 1# | 465 | 360 | 39 |

| I | 2# | 435 | 355 | 40 |

| II | 3# | 415 | 315 | 42 |

| II | 4# | 415 | 310 | 42 |

Effects of Annealing Temp. on Microstructure of Titanium Grade 2

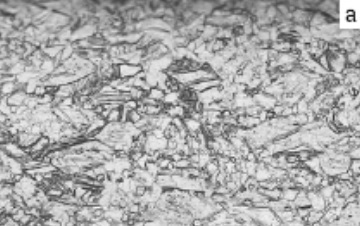

Microstructure of titanium grade 2 seamless tubes after annealing at 550°C.

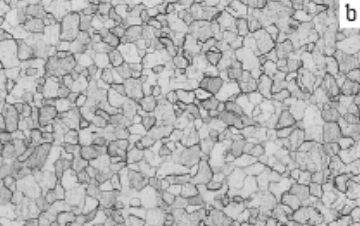

Microstructure of titanium grade 2 seamless tubes after annealing at 600°C.

Analysis & Conclusion: all mechanical properties after either annealing at 550°C or annealing at 600°C can meet the tensile requirements of ASTM B338 grade 2 titanium. However, as shown in the metallographic photo [a], the recystallization is incomplete at 550°C while considerable cold-worked structures are visible. In photo [b], the recystallization is complete with equiaxed grain. The strain hardening is eliminated during 600°C annealing. Hence, relatively lower strength and better ductility are obtained. Usually for grade 2 titanium tubes, the annealing temperature shall be at 600°C.