Duplex 2507

Designated as UNS S32750 or DIN W.Nr. 1.4410, Duplex 2507 is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity, and a low coefficient of thermal expansion. The high chromium, molybdenum, and nickel levels provide excellent resistance to pitting, crevice, and general corrosion.

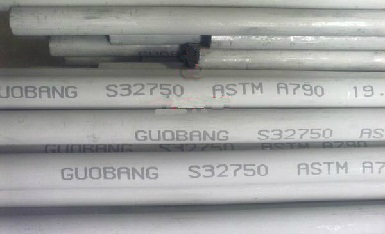

ASTM A790 UNS S32750(duplex 2507) seamless pipe 3/8″ SCH10S.

1. Chemical Composition of Duplex 2507

| The Chemical Composition of SS2507, % | |

|---|---|

| C | ≤0.03 |

| Mn | ≤1.2 |

| Si | ≤0.80 |

| S | ≤0.02 |

| P | ≤0.035 |

| Cr | 24.0-26.0 |

| Ni | 6.0-8.0 |

| Mo | 3.0-5.0 |

| Cu | ≤0.5 |

| N | 0.24-0.32 |

2. Mechanical Properties of Duplex 2507

| Tensile Strength | Yield Strength | Elongation | Hardness | Impact Test |

|---|---|---|---|---|

| ksi(Mpa) | ksi(Mpa) | % | HRC | ft.lbf |

| ≥110(800) | ≥80(550) | ≥25 | ≥32 | ≥74 |

3. Manufacture, Heat Treatment & Weldability

Duplex 2507 piping materials can be manufactured by hot forming or cold forming methods. The hot forming temperature shall be between 1875°F and 2250°F. This should be followed by solution annealing at 1925°F minimum and a rapid air or water quench. The cold forming includes bending, deep drawing, extruding and pressing. After the cold forming process, the heat treatment of solution annealing and quenching is required. Besides, 2507 duplex stainless steels have good weldability.