Cast Tungsten Carbide Powder

Characteristics and Production Process

The cast tungsten carbide powder has a WC and W2C eutectic structure which exhibits dark gray appearance. It exhibits outstanding wear- and impact-resistance, as well as high hardness property, at high temperatures. The sizes of tungsten carbide particle range from 0.038 mm to 2.362 mm. Hardness: 93.0~93.7 HRA; micro-hardness: 2500~3000 kg/mm2; density: 16.5 g/cm3; melting point: 2525°C.

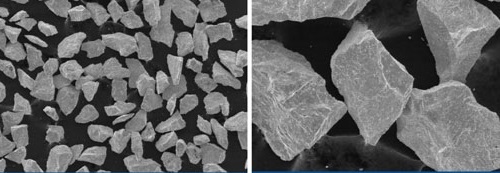

Microstructure of cast tungsten carbide particle by SEM

Cast tungsten carbide powder is produced by an advance process: metal tungsten and tungsten carbide powders are mixed and packed into a graphite boat. Together, they are heated in a melting furnace at 2900°C and held for a certain time to obtain casting block consisting of WC and W2C eutectic phases with grain size of 1~3 μm.

Chemical Composition of Cast Tungsten Carbide Powder

| Grade | Chemical Composition Requirements (wt %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. | W | T.C. | F.C. | Ti | Ni | Cr | V | Si | Fe | O |

| MG-A | 95~96 | 3.8~4.1 | ≤0.08 | ≤0.10 | - | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.30 | ≤0.05 |

| MG-B | 92~93 | 3.8~4.1 | ≤0.08 | ≤0.10 | 2.5~3.5 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.30 | ≤0.05 |

| MG-C | 91~92 | 3.8~4.1 | ≤0.08 | ≤0.10 | 3.5~4.5 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.30 | ≤0.05 |

| MG-D | 90~91 | 3.8~4.1 | ≤0.08 | ≤0.10 | 4.5~5.5 | ≤0.10 | ≤0.05 | ≤0.02 | ≤0.30 | ≤0.05 |

Cast Tungsten Carbide Particle Sizes

| Type | Sieve Size | Particle Size |

|---|---|---|

| Series No. | Mesh | μm |

| WC8-12M | -8~+12 | 2362~1397 |

| WC10-20M | -10~+20 | 2000~850 |

| WC20-30M | -20~+30 | 850~600 |

| WC30-40M | -30~+40 | 600~425 |

| WC40-60M | -40~+60 | 425~250 |

| WC60-80M | -60~+80 | 250~180 |

| WC80-200M | -80~+200 | 180~75 |

| WC200-400M | -200~+400 | 75~38 |

| WC400M | -400 | 38 |

Applications of Cast Tungsten Carbide Powder

The cast tungsten carbide can be deposited to the wear or abrasion surface by oxyacetylene welding, arc welding, thermal spray, or brazing. It may firmly adhere to the surface of work piece with epoxy resin and inorganic additives in low-temperature and -impact applications. The tungsten carbide coating imparts high-temperature wear resistance, excellent impact toughness, long life expectancy, low cost and easy maintenance to the work pieces. The material is widely applied for mining, petroleum and construction industry, agriculture machinery, and steel industry, etc.