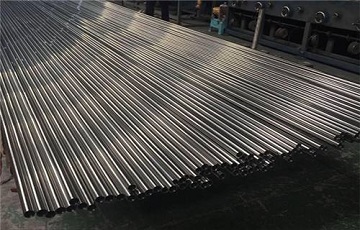

ASTM A789 UNS S31803 Tubing

Material Characteristics

The ASTM A789 UNS S31803 tubing refers to seamless and welded tubing manufactured in accordance with ASTM A789/ASTM A1789M, which contains approximately 50% ferrite and 50% austenite. The stress corrosion resistance of ASTM A789 in neutral chloride solution and H2S is better than that of 304L, 316L austenitic stainless steel, and 18-5mo type duplex stainless steel. The UNS S31803 tubing is especially suitable for the temperature range of -50°F/+600°F. It may also be considered for applications beyond this temperature range, but there are some limitations, especially when applied to weld structures.

Manufacture & Heat Treatment

The ASTM A789/A789M UNS 31803 tubes shall be made by the seamless or welded process with no filler metal added. It shall be quenched in cool air or water rapidly to a temperature of 1800°F[980°C]-1900°F[1040°C]. For seamless tubes, as an alternative to final heat treatment in a continuous furnace or batch-type furnace, while the tube temperature is not lower than the specified minimum solution treatment temperature, tubes may be immediately quenched in water or rapidly cooled by other means.

Chemical Composition Requirements

| Chemical composition for ASTM A789 UNS S31803 tubing, % | |

|---|---|

| C | ≤0.030 |

| Mn | ≤2.00 |

| P | ≤0.030 |

| S | ≤0.020 |

| Si | ≤1.00 |

| Ni | 4.5-6.5 |

| Cr | 21.0-23.0 |

| Mo | 2.5-3.5 |

| N | 0.08-0.20 |

Mechanical Properties

| Tensile Strength,min. | Yield Strength,min. | Elongation,min. | Hardness Brinell, max |

|---|---|---|---|

| Mpa | Mpa | % | HB |

| 620 | 450 | 25 | 290 |

Tests and Inspection

A tensile test should be performed on samples with no more than 50 roots for ASTM A789 UNS S31803 tubing. For more than 50 tubes, a tensile test should be carried out on samples of two tubes. Flaring test(for seamless tubes) and flange test(for welded tubes) shall be performed on one end of each finished tube. The minimum expansion of the inner diameter is 10%. When required by the purchaser, the hydrostatic test shall be in accordance with specification A1016/A1016M, but the hydrostatic test pressure shall be calculated by 64000(441.2) instead of 32000(220.6).