ASTM A420 Carbon & Alloy Steel Pipe Fittings for Low-Temperature Service

ASTM A420 is the standard specification for pipe fittings of wrought carbon steel and alloy steel for low temperature service. These fitting, either of seamless or welded construction, are primarily used in pressure piping and pressure vessel service at low temperatures. Metals-Piping can provide all the four steel grades covered by ASTM A420: WPL6, WPL9, WPL3, and WPL8.

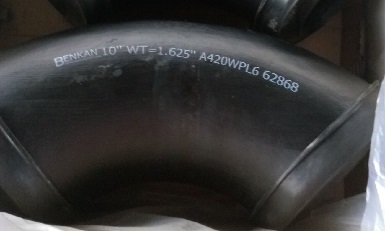

90° L/R elbow, ASTM A420 WPL6, 10″ w.t=1.625″(42 mm). Compound bevel ends with plastic-protection caps.

1. ASTM A420 Chemical Composition Requirements

| Chemical Composition of ASTM A420 | ||||

|---|---|---|---|---|

| Elements | WPL6, % | WPL9, % | WPL3, % | WPL8, % |

| Carbon [C] | ≤0.30 | ≤0.20 | ≤0.20 | ≤0.13 |

| Manganese [Mn] | 0.50-1.35 | 0.40-1.06 | 0.31-0.64 | ≤0.90 |

| Phosphorus [P] | ≤0.035 | ≤0.030 | ≤0.05 | ≤0.030 |

| Sulfur [S] | ≤0.040 | ≤0.030 | ≤0.05 | ≤0.030 |

| Silicon [Si] | 0.15-0.40 | … | 0.13-0.37 | 0.13-0.37 |

| Nickel [Ni] | ≤0.40 | 1.60-2.24 | 3.2-3.8 | 8.4-9.6 |

| Chromium [Cr] | ≤0.30 | ... | ... | ... |

| Molybdenum [Mo] | ≤0.12 | ... | ... | ... |

| Copper [Cu] | ≤0.40 | 0.75-1.25 | … | … |

| Columbium [Cb] | ≤0.02 | ... | ... | ... |

| Vanadium[V] | ≤0.08 | ... | ... | ... |

*Fittings of WPL3 made from plate or forgings may have 0.90 % max manganese.

*Fittings of WPL8 made from plate may have 0.98 % max manganese.

2. ASTM A420 Mechanical Properties

| ASTM A420/ A420M | Tensile Strength, min. | Yield Strength, min. | Elongation %, min | |||

|---|---|---|---|---|---|---|

| Grade | ksi | MPa | ksi | MPa | Longitudinal | Transverse |

| WPL6 | 65-95 | 415-655 | 35 | 240 | 22 | 12 |

| WPL9 | 63-88 | 435-610 | 46 | 315 | 20 | … |

| WPL3 | 65-90 | 450-620 | 35 | 240 | 22 | 14 |

| WPL8 | 100-125 | 690-865 | 75 | 515 | 16 | … |

3. Impact Test Properties

Since these pipe fittings are primarily used for low-temperature service, the properties of charpy V-notch impact test must be considered.

| Charpy Impact Requirements for WPL6, WPL9, and WPL3 | ||||

|---|---|---|---|---|

| Size of Specimen | A* | B* | ||

| mm | ft·lbf | J | ft·lbf | J |

| 10 by 10.0 | 13 | 17.6 | 10 | 13.6 |

| 10 by 7.5 | 10 | 13.6 | 8 | 10.8 |

| 10 by 5.0 | 7 | 9.5 | 5 | 7.0 |

| 10 by 2.5 | 4 | 5.4 | 3 | 4.1 |

B*Minimum Charpy V-Notch Impact Value Without Requiring Retest (One Specimen Only of a Set)

| Charpy Impact Requirements for WPL8 | ||||

|---|---|---|---|---|

| Size of Specimen | A* | B* | ||

| mm | ft·lbf | J | ft·lbf | J |

| 10 by 10.0 | 25.0 | 33.9 | 20.0 | 27.1 |

| 10 by 7.5 | 21.0 | 28.5 | 17.0 | 23.1 |

| 10 by 5.0 | 17.0 | 23.1 | 14.0 | 19.0 |

| 10 by 2.5 | 8.0 | 10.8 | 6.0 | 8.1 |

B*Minimum Charpy V-Notch Impact Value Without Requiring Retest (One Specimen Only of a Set)

| Impact Test Temperature | |

|---|---|

| Grade | °F [°C] |

| WPL6 | −50 [−45] |

| WPL9 | −100 [−75] |

| WPL3 | −150 [−100] |

| WPL8 | −320 [−195] |

4. Material and Manufacture

The raw material for these fittings shall be fully killed steel, consisting of forgings, bars, plates, sheet, and seamless or fusion welded tubular products(pipes, tubes, or cylinders). The steels shall be made using recognized melting practices necessary to produce steels that shall meet the impact requirements of ASTM A420.

Conc. reducer 10″x6″(wt. 1.625″x1.062″), ASTM A420 WPL6.

The ASTM A420 fittings may be made by forging or forming operations including hammering, pressing, piercing, extruding, upsetting, working, bending, fusion-welding, or machining, or by a combination of two or more of these operations. The forming procedure shall be so applied that it will not produce injurious defects in the fittings. All the fittings shall be furnished free of welding repair. The welded joints of the fittings shall be finished in accordance with the requirements of Paragraph UW-35 (a) of Section VIII, Division 1 of ASME Boiler and Pressure Vessel Code.

5. Heat Treatment

All fittings shall be furnished in the normalized, normalized and tempered, annealed, or quenched and tempered condition. All welding shall be completed prior to the austenitizing heat treatment. After forming, the fittings shall be allowed to cool below the lower critical before applying one of the heat treatments. When specified, post-weld heat treatment may be required.

6. Product & Standards

| Standards | Product |

|---|---|

| ASME B16.9 | Factory-Made Wrought Steel Butt Welding Threaded |

| ASME B16.11 | Forged Steel Fittings, Socked Welding Threaded |

| ASME Section VIII Division 1 | Pressure Vessels |

| MSS SP-25 | Standard Marking System for Valves, Fittings, Flanges, and Unions |

| MSS SP-79 | Socket Welding Reducer Inserts |

| MSS SP-83 | Steel Pipe Unions, Socket-Welding and Threaded |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

| MSS SP-97 | Integrally Reinforced Forged Branch Outlet Fittings-Socket Welding, Threaded and Buttwelding Ends |

7. Tests and Inspections

Pipe fittings manufactured to ASTM A420 shall take the following tests or inspections: dimensional inspection, visual examination, hydrostatic test(when required), chemical analysis, tensile test, impact test, radiographic test(RT).