ASTM A420 Grade WPL6

Pipe fittings of ASTM A420 WPL6 are widely utilized in pressure piping and pressure vessel service at low-temperatures. They can be furnished in accordance with a variety of ASME and MSS standards. According to ASME Boiler and Pressure Vessel Code, ASTM A420 WPL6 is not permitted for use in the construction of power boiler. However, it can be used for ASME Section III, Section VIII Division 1, and Section XII with maximum applicable temperature of 700°F, 850°F, and 650°F respectively. It pertains to material Group 1 designated with P-Number 1.

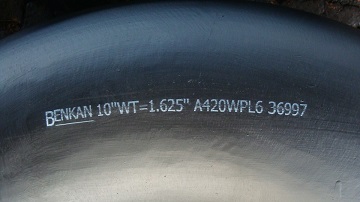

A 90° elbow manufactured to ASTM A420 Gr. WPL6. 10″ w.t=1.625″, L/R.

1. Chemical Composition of ASTM A420 WPL6

| C | Mn | P | S | Si | Ni | Cr | Mo | Cu | Cb | V |

|---|---|---|---|---|---|---|---|---|---|---|

| ≤0.30 | 0.50~1.05 | ≤0.035 | ≤0.040 | 0.15~0.40 | ≤0.40 | ≤0.30 | ≤0.12 | ≤0.40 | ≤0.02 | ≤0.08 |

2. Mechanical Properties of ASTM A420 WPL6

| Tensile Strength, min. | Yield Strength, min. | Elongation (2 in.), min. | |||

|---|---|---|---|---|---|

| ksi | MPa | ksi | MPa | Longitudinal, % | Transverse, % |

| 60~95 | 415~655 | 35 | 240 | 30 | 16.5 |

3. Charpy Impact Requirements

| Size of Specimen | A* | B* | ||

|---|---|---|---|---|

| mm | ft·lbf | J | ft·lbf | J |

| 10 by 10.0 | 13 | 17.6 | 10 | 13.6 |

| 10 by 7.5 | 10 | 13.6 | 8 | 10.8 |

| 10 by 5.0 | 7 | 9.5 | 5 | 7.0 |

| 10 by 2.5 | 4 | 5.4 | 3 | 4.1 |

*B – Minimum Charpy V-Notch Impact Value Without Requiring Retest (One Specimen Only of a Set).

*The impact test temperature shall be -50°F[-45°C] for ASTM A420 Gr. WPL6.

4. Maximum Allowable Stress at Elevated Temperatures

| Temp. | -20~100 | 150 | 200 | 300 | 400 | 500 |

| *MAS | 17.1 | 17.1 | 17.1 | 17.1 | 17.1 | 17.1 |

| Temp. | 600 | 650 | 700 | 750 | 800 | 850 |

| *MAS | 17.1 | 17.1 | 15.6 | 13.0 | 10.8 | 8.7 |

5. Design Stress Intensity at Elevated Temperatures

| *Temp. | -20~100 | 150 | 200 | 300 | 400 | 500 | 600 | 650 | 700 |

|---|---|---|---|---|---|---|---|---|---|

| *DSI | 20.0 | 20.0 | 20.0 | 20.0 | 19.9 | 19.0 | 17.9 | 17.3 | 16.8 |

6. Tensile Strength at Elevated Temperatures

| *Temp. | -20~100 | 200 | 300 | 400 | 500 | 600 | 650 |

| *TS | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 |

| *Temp. | 700 | 750 | 800 | 850 | 900 | 950 | 1000 |

| *TS | 60.0 | 59.3 | 55.1 | 50.2 | 44.8 | 39.4 | 34.6 |

7. Yield Strength at Elevated Temperatures

| *Temp. | -20~100 | 150 | 200 | 250 | 300 | 400 | 500 | 600 |

| *YS | 35.0 | 32.9 | 32.1 | 31.5 | 31.0 | 22.9 | 28.5 | 26.8 |

| *Temp. | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 |

| *YS | 25.9 | 25.1 | 24.2 | 23.5 | 22.8 | 22.1 | 21.5 | 20.8 |