Nickel 201

Designated as UNS N02201 or W.Nr. 2.4061 & 2.4068, Nickel 201 is has almost identical chemical composition as Nickel 200 except the lower-carbon content. Nickel 201 is typically applied in caustic evaporators, combustion boats, plater bars, as well as electronic components. Compared to Nickel 200, Nickel 201 has much lower base hardness and lower work-hardening rate hence is particularly suited for spinning and cold forming. According to ASME Boiler and Pressure Vessel Code Section VIII-Division 1, Nickel 201 is approved for construction of pressure vessels for service up to 1250°F. Its mechanical properties also vary depending on the manufacture process and heat treatment conditions.

Pipe length of Nickel 201, 3″ W.T=8 mm, ASTM B161 UNS N02201.

1. Chemical Composition Requirements

| Chemical Composition of Nickel 201, % | |

|---|---|

| Nickel(plus Cobalt) | ≥99.0 |

| Copper | ≤0.25 |

| Iron | ≤0.40 |

| Manganese | ≤0.35 |

| Carbon | ≤0.02 |

| Silicon | ≤0.35 |

| Sulfur | ≤0.01 |

2. Physical Properties

| Physical Properties of Nickel 201 | |||||||

|---|---|---|---|---|---|---|---|

| Density | Specific Heat | Curie Temperature | Modulus of Elasticity (Tension) | ||||

| lb/in3 | g/cm3 | Btu/lb*°F | J/kg*°C | °F | °C | 103 ksi | GPa |

| 0.321 | 8.89 | 0.109 | 456 | 680 | 360 | 30 | 207 |

3. Product Forms and Standards

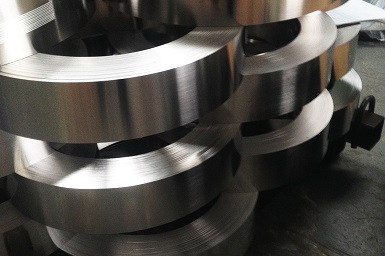

Nickel 201 strip in coils, 60 mm x 1.25 mm thick.

| Nickel 201: Product Forms and Relative Standards | |

|---|---|

| Products Form | Standard |

| Rod and bar | ASTM B160, DIN 17752, ISO9723, VdTUV 345 |

| Pipe and Tube | ASTM B161, B163, B725, B730, B751, B775, B829, DIN 17751, ISO 6207, BS 3074(NA 12), VdTUV 345 |

| Plate, Sheet & Strip | ASTM B162, DIN 17750, ISO 6208, BS3072-3073(NA 12), SAE AMS 5553, VdTUV 345 |

| Fittings | ASTM B366 |

| Forgings | ISO 9725, DIN 17754 |

| Wire | DIN 17753, ISO 9724 |