Titanium Clad Steel Plate

General Introduction

The titanium-clad steel plate is a typical metallic laminar composites. It is also known as titanium cladding or titanium-steel bimetallics. Usually, they are produced by deformation bonding: either hot/cold-roll bonding or explosive bonding. The titanium clad steel plate obtains the low cost and high strength of steel with the outstanding corrosion resistance of titanium.

Standard & Specification

ASTM A516 grade 70 steel plates with ASTM B265 titanium Gr.2 cladding.

The titanium-clad steel plate shall be manufactured to ASTM B898. The base metal may be a variety of carbon steel plates manufactured to ASTM A516, ASTM A515, ASTM A266, ASTM A572, ASTM A709, ASTM A387, ASTM A240, etc. The cladding metal may be ASTM B265 titanium Gr.1, Gr.2, Gr.3, Gr.7, Gr.9, Gr.12, and Gr.16, etc. The cladding techniques can be either hot rolling, cold rolling, explosive bonding, or a combination of them. Size specification: thickness(0.5 mm~16 mm), width x length range(2m x 6m).

Applications

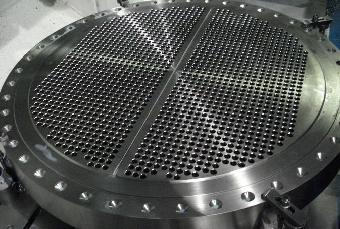

A titianium gr.2 clad tube sheet for a heat exchanger in Chile power plant. The base metal is steel plate made to ASTM A387 Gr.22.

The titanium clad steel plates are widely used in many applications and services. These include petrochemical & chemical industry especially chloral alkali process, food industry, fertilizer industry, wet metallurgy, electroplating, vacuum salt production, marine engineering, chimney industry, pressure vessels, heat exchangers, desalination industry, and power plant, etc.