Titanium & Titanium Alloy Castings

Titanium & titanium alloy castings are widely used for general corrosion-resistant and industrial applications. There are several grades available: Grade C-2, Grade C-3, Grade C-5, Grade C-6, Grade C-7, Grade C-8, Grade C-9, Grade C-12, Grade C-16, Grade C-17, Grade C-18, Grade C-38. Typically, valves made from titanium or titanium alloy castings are commonly seen in various applications.

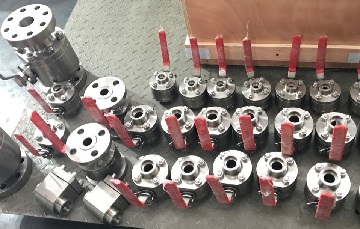

Cast titanium ball valves, ASTM B367 Gr. C-3.

Material and Manufacture

Materials for titanium & titanium alloy castings shall be melted by conventional processes used for reactive metals. Typical methods include the consumable electrode and induction slag, plasma arc, induction-skull, and electron beam melting processes.

Heat Treatment

- Unless otherwise specified by the purchaser, all titanium & titanium alloy castings of ASTM B367 shall be supplied in the as-cast condition except when post-weld heat treatment is required.

- If post-weld heat treatment is required, it shall consist of a stress relief performed at 1075 ± 25°F (580 ± 14°C) for Grades C-2, C-3, C-7, C-8, C-12, C-16 and C-17, and 1200 ± 25°F (650 ± 14°C) for Grades C-5, C-6, C-9, C-18, and C-38. Time at temperature shall be a minimum of 0.5 h plus an additional 0.5 h at temperature per inch of thickness for section sizes greater than 1 in. (25 mm). After heat treatment, the castings should be cooled in air or in the furnace to ambient temperature unless otherwise agreed upon between the purchaser and producer.

- When required, hot isostatic pressing(HIP) process shall be used to improve as-cast quality of the titanium & titanium alloy.