The Manufacture of Incoloy 825 Welding Neck Flanges

Incoloy 825 welding neck flanges are widely used in sour crude oil services. The primary manufacturing processes include: electric arc furnace melting → ingot casting → cogging → descaling → cutting → preheating → loose tooling forging → heat treatment → machining → inspection.

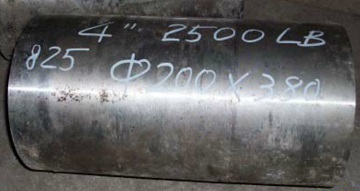

The cogging of Incoloy 825 cast ingot.

The Incoloy 825 billet after descaling & cutting.

The preliminary forging of the billet.

The final loose tooling foring.

There are some difficulties in the manufacturing of Incoloy 825 flanges: (1) the material has very high resistance to deformation: even at 980°C, its flow stress can be as high as 240 MPa. (2) In order to prevent the intergranular corrosion and improve its resistance to hydrogen sulfide stress corrosion, fined grain is required. However, phase transformation is not available when Incoloy 825 is heated or cooled. Fined grain can only be achieved by re-crystallization or plastic deformation. (3) The deformation on each direction shall be 15% larger than the critical values to avoid coarse grain.

The completed forging of ASTM B564 UNS N08825.

The flange machining process.

The finished products: Incoloy 825 welding neck flanges, RTJ Class 1500, 2″ SCH160.