Incoloy 800H

Incoloy 800H, also known as “Alloy 800H”, is designated as UNS N08810 or DIN W.Nr. 1.4958. It has almost the same chemical composition as Alloy 800 except that it requires a higher carbon addition resulting in improved high-temperature properties. Compared to Incoloy 800, it has better creep and stress-rupture characteristics in the 1100°F [592°C] to 1800°F [980°C] temperature range. While Incoloy 800 is usually annealed at at approximately 1800°F [980°C], Incoloy 800H should be annealed at approximately 2100°F [1150°C]. Besides, Alloy 800H has a coarser average grain size in accordance with ASTM 5.

Incoloy 800H seamless pipes cut into pieces. O.D=180mm, THK=18mm.

1. Chemical Composition Requirements

| The Chemical Composition of Incoloy 800, % |

| Nickel | 30.0-35.0 |

| Cromium | 19.0-23.0 |

| Iron | ≥39.5 |

| Carbon | 0.05-0.10 |

| Aluminum | 0.15-0.60 |

| Titanium | 0.15-0.60 |

| Manganese | ≤1.50 |

| Sulfur | ≤0.015 |

| Silicon | ≤1.00 |

| Copper | ≤0.75 |

| Al+Ti | 0.30-1.20 |

2. Mechanical Properties of Incoloy 800H

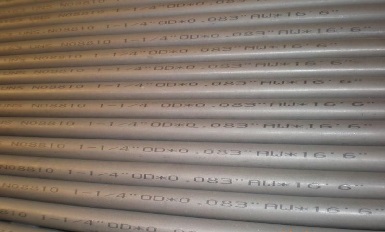

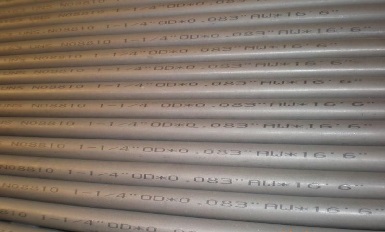

ASTM B163 UNS N08810, Incoloy 800H seamless pipes, 1-1/4″ x 0.083″(W.T) x 16.6′(L).

| Tensile Strength, min. | Yield Strength, min. | Elongation, min. | Hardness, min. |

| Mpa | ksi | Mpa | ksi | % | HB |

| 600 | 87 | 295 | 43 | 44 | 138 |

3. Physical Properties of Incoloy 800H

| Density | Melting Range | Specific Heat | Electrical Resistivity |

| g/cm3 | °C | °F | J/kg. k | Btu/lb.°F | µΩ·m |

| 7.94 | 1357-1385 | 2475-2525 | 460 | 0.110 | 989 |

4. Product Forms and Standards of Incoloy 800H

| Product From | Standard |

| Rod and Bar | ASTM B408, EN 10095 |

| Plate, Sheet & Strip | ASTM A240, A480, ASTM B409, B906 |

| Seamless Pipe & Tube | ASTM B829, B407 |

| Welded Pipe & Tube | ASTM B514, B515, B751, B775 |

| Welded fittings | ASTM B366 |

| Forging | ASTM B564, DIN 17460 |

Related Items